Buttweld 90° Elbow Specification:

| 形式/Type | 等径(1.0D、1.5D、3D、5D、8D、10D……)Straight Radius 非标带直边Non-standard with Straight end. |

| 原材料/Raw Material | 无缝管、焊管(SS)、板焊、圆钢(锻制高压用)。Seamless pipe, Welded pipe, Steel sheet. Round bar(Foring High pressure) |

| 制作工艺/Manufacture Process | 挤压、热压、冷加工、热加工、焊接、热处理 。Extrusion moulding, Hot Pressing, Cold-machining, Hot-machining, Welded, Heat treatment |

| 尺寸外径/Outside Diameter | Seamless Elbow ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″) |

| 壁厚压力/Wall Thickness | 3mm – 40mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| 弯头角度/Product’s Angle | 5° – 180° Elbows, 90° and 45° Long Radius Elbows, Long Radius Returns, Short Radius Elbows and Returns |

| 弯曲半径/Bending Radius | R=1D – 10D, 15D, 20D |

| 增值服务/Value Added Services | 热浸镀锌,环氧树脂和FBE涂层,电抛光,喷砂,螺纹加工,焊接(Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering) |

| 制造标准/Manufacturing Standards | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, GB/T12459, GB/T13401, SH3408, SH3409, JIS B2311/2220, DIN2617/2616/2615 |

Buttweld 90° Elbow Material Grades:

| 不锈钢/Stainless Steel | ASTM A403 WP304, 304L, 304H, 309, 310, 316, 316L, 317L, 321, 347 |

| 碳钢/Carbon Steel | 20#, 20G,Q235-A, ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

| 低温钢/Low Temperature Carbon Steel | 16Mn, ASTM A420 WPL3, A420 WPL6 |

| 合金钢/Alloy Steel | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91, WB36, 12CrMo, 15Cr5Mo, 1Cr5Mo, 12Cr1MoV |

| 双相不锈钢钢/Duplex Steel | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. S31254, 254SMO, S32750,904L |

| 镍合金/Nickel Alloy Steel | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

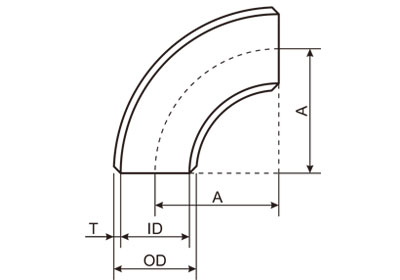

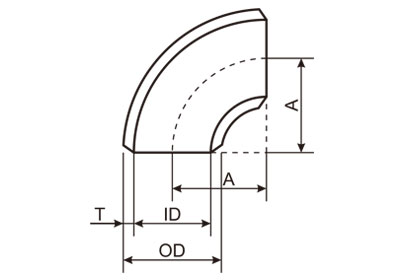

Buttweld 90° Elbow Dimensions

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel D | Center to End | |||

| Long Radius Elbows | Short Radius Elbows | ||||

| 90 degree A | 45 degree A | 90 degree A | 45 degree A | ||

| 1/2 | 21.3 | 38.1 | 15.7 | — | — |

| 3/4 | 26.7 | 38.1 | 19.1 | – | – |

| 1 | 33.4 | 38.1 | 22.4 | 25.4 | – |

| 11/4 | 42.2 | 47.8 | 25.4 | 31.8 | – |

| 11/2 | 48.3 | 57.2 | 28.4 | 38.1 | – |

| 2 | 60.3 | 76.2 | 35.1 | 50.8 | – |

| 21/2 | 73 | 95.2 | 44.4 | 63.5 | – |

| 3 | 88.9 | 114.3 | 50.8 | 76.2 | 31.6 |

| 31/2 | 101.6 | 133.4 | 57.2 | 88.9 | 36.8 |

| 4 | 114.3 | 152.4 | 63.5 | 101.6 | 42.1 |

| 5 | 141.3 | 190.5 | 79.2 | 127 | 52.6 |

| 6 | 168.3 | 228.6 | 95.2 | 152.4 | 63.4 |

| 8 | 219.1 | 304.8 | 127 | 203.2 | 84.2 |

| 10 | 273.1 | 381 | 158.8 | 254 | 105.2 |

| 12 | 323.9 | 457.2 | 190.5 | 304.8 | 126.3 |

| 14 | 355.6 | 533.4 | 222.2 | 355.6 | 147.3 |

| 16 | 406.4 | 609.6 | 254 | 406.4 | 168.3 |

| 18 | 457.2 | 685.8 | 285.8 | 457.2 | 189.4 |

| 20 | 508 | 762 | 317.5 | 508 | 210.4 |

| 22 | 558.8 | 838.2 | 342.9 | 558.8 | 231.5 |

| 24 | 609.6 | 914.4 | 381 | 609.6 | 252.5 |

| 26 | 660.4 | 990.6 | 406.4 | 660.4 | 273.5 |

| 28 | 711.2 | 1066.8 | 438.2 | 711.2 | 294.6 |

| 30 | 762 | 1143 | 469.9 | 762 | 315.6 |

| 32 | 812.8 | 1219.2 | 501.6 | 812.8 | 378.1 |

| 34 | 863.6 | 1295.4 | 533.4 | 863.6 | 357.7 |

| 36 | 914.4 | 1371.6 | 565.2 | 914.4 | 378.8 |

| 38 | 965.2 | 1447.8 | 599.9 | – | – |

| 40 | 1016 | 1524 | 632 | 1016 | 420.8 |

| 42 | 1066.8 | 1600.2 | 660.4 | 1066.8 | 441.9 |

| 44 | 1117.6 | 1676.4 | 695.5 | 1117.6 | 462.9 |

| 46 | 1168.4 | 1752.6 | 726.9 | – | – |

| 48 | 1219.2 | 1828.8 | 759 | 1219.2 | 505 |

| 52* | 1320.8 | – | – | 1320.8 | 547.1 |

| 54* | 1371.6 | 2057.4 | 852.2 | 1371.6 | 568.1 |

| 56* | 1422.4 | 2133.6 | 883.8 | 1422.4 | 589.2 |

| 60* | 1524 | 2286 | 946.9 | 1524 | 631.3 |

| 66* | 1676.4 | 2514.6 | 1041.6 | – | – |

| 68* | 1727 | 2591 | 1073 | 1727 | – |

| 72* | 1829 | 2743 | 1137 | 1829 | – |

| 76* | 1930 | 2896 | 1199 | 1930 | – |

| 80 | 2032 | 3048 | 1263 | 2032 | – |